| Fluidized Bed Classifying Jet Mill | |||||||||||||||||||||||||||||||||||||||||||||||||

+ Fluidized Bed Classifying Jet Mill + Precision Air Classifier + Classifying Impact Mill + Abrasive Powder Classifying Jet Mill/ Shaping + Bag Collector + Ultrafine Powder Processing Line |

|

||||||||||||||||||||||||||||||||||||||||||||||||

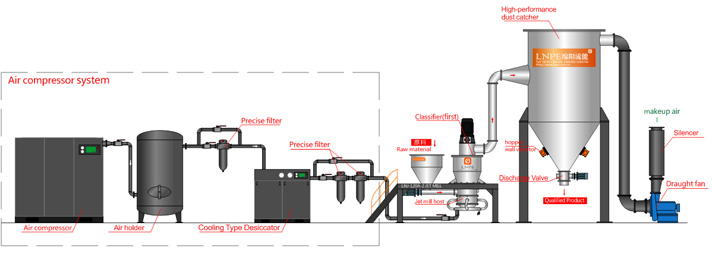

| Working Principle : LNJ Jet Mill is a device as using multiple nozzles to form sonic speed air flow to perform superfine pulverizing. The ground materials will be brought to high-efficient turbine classifier, the coarser particles will be swirled back to grinding chamber for further grinding. LNJ Jet Mill is a superfine grinding equipment based on the theoretical research and numerical simulation, combined domestic and foreign advanced technology. Perfect structure and flow field design, greatly improving the high-speed airflow and classifier efficiency Customized design to solve different affairs. Feature: 1.Low energy consumption 2.Materials collision each other without contamination, effective for Mohs 1-10 hard material 3.Fully automatic control, easy to operate. 4.Omniseal negative pressure operation, no contamination |

|||||||||||||||||||||||||||||||||||||||||||||||||

| ■Application field | |||||||||||||||||||||||||||||||||||||||||||||||||

| [high purity and super-hard material] Typical materials:fluorescent powder, titanium dioxide, silicon, copper and other high purity pigment, etc. [fine chemicals ,ceramics, abrasive and refractories] Typical materials:garnet, silicon carbide, corundum, ceria, aluminium oxide, boric oxide, tungsten carbide and emery, etc [food, pharmaceutical and health products] Typical material:pollen, hawthorn, pearl powder, Nimodipine, antibiotic, contrast agent, glossy ganoderma, Chinese galls, polygonum multiflorum thunb,etc.? [magnetic powder, mobile phone electromagnetic powder, photocopy toner and electronic material] Typical material: lead acid battery, Ni-Cd battery, Ni-Mn battery, ferrite, Trimanganese tetroxide, manganese dioxide, LiCoO2, lithium manganese oxide, carbon, etc. [non-metallic mineral and powder metallurgy] Typical material: quaraz, barite, kaolinite, triple superphosphate, talc, mica, graphite, wollastonite, etc. [reflectoriy material, pigments and powder paint] Typical material:iron oxide, titanium dioxide、glass bead, etc. [pesticide, feedstuff and biomaterials] |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| ■Main technical parameter | |||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||